Enhancing Quality Assurance at ArcelorMittal Rodange Plant

ArcelorMittal Rodange, a leading plant in rolling profiles for the construction and infrastructure industries, has chosen Zumbach Electronic AG again as its trusted supplier for the measurement of their products. Our products offer significant advantages and meet the specific requirements of the ArcelorMittal Rodange plant.

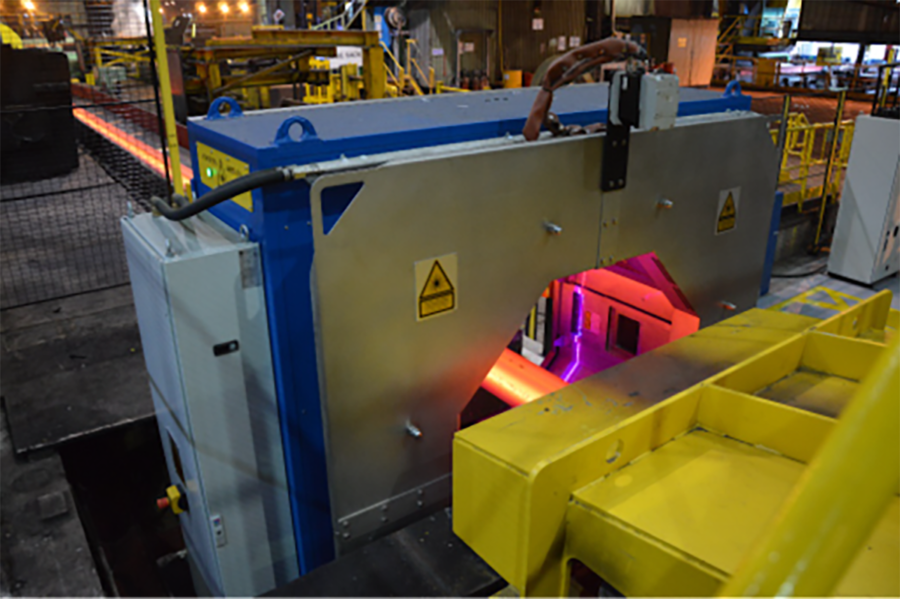

At the ArcelorMittal Rodange plant, the imported blooms/billets are heated in an oven up to +/- 1100°C. Once the product is achieved the blooms and billets are being rolled to the desired profiles. Then the rolled profiles are being checked and measured with our SPS 800-8K system before passing to the cooling table. Simultaneously a report of each profile is generated and the statistics and SPC reports of all profiles and the whole production is saved. All reports are automatically uploaded to the SteelDATA Manager software. These reports can be checked later on via Zumbach SteelDATAViewer.

To enhance the quality of their finished products, ArcelorMittal Rodange ordered another SPS 400-8K system for their finishing department. This ensures that every produced product can be checked another time before being shipped to the final customers. This machine will be installed at the end of 2023.

Another benefit of the PROFILEMASTER® SPS for their production process is that it is possible to see the complete contour of the product during the production process, at a product temperature of +/- 1000°C. This way, they can adjust the rolling mill much faster, so they don’t have to wait until the product is finished and cooled down, thus reducing the quantity of scrap and product variation.

The choice of Zumbach Electronic AG as their supplier was also driven by competitive pricing, providing a cost-effective solution without compromising on quality. Additionally, the confidence gained from witnessing Zumbach’s products in operation at other companies solidified ArcelorMittal Rodange’s trust in the reliability and effectiveness of our products.