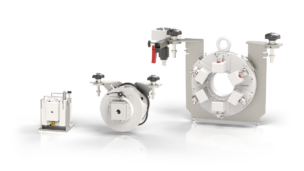

RAYEX® S

X-ray measuring device for measuring

wall thickness, eccentricity, diameter and ovality

of cables, tubes and hoses

Properties

- Wall thickness testing from 0.3 mm

- Measuring of product sizes between 4 mm … 100 mm

- Option for multi-layer measurement

- Radiation protection thanks to safety concept

- Durable X-ray sources

- Communication via integrated interfaces such as Ethernet IP, Profinet IO or Ethernet TCP/IP

- Integrated web server in all processor versions

- Easy product recipe

Benefits

- All in one! Complete system for measuring wall thickness, ovality, eccentricity and diameter

- Calibratable and certifiable solution

- Measuring accuracy independent of external process influences such as the material temperature

- Automatic control of the line speed or the extruder output capacity

- Short start-up time

Number of measuring axes

Min. object diameter (mm)

Max. object diameter (mm)

Scan rate (scans/s)

Technical data

For accessories and detailed product information, refer to the respective brochures

RAYEX S 50

- Measuring axes

- 2

- Object diameter

- 4.0 … ca. 45 mm

- Min. wall thickness

- 0.3 mm

- Scan rate

- 1 … 10/s

- Brochure

- Rayex S 50 (PDF, 2.01 MB)

RAYEX S 110

- Measuring axes

- 2

- Object diameter

- 7.0 … 100 mm

- Min. wall thickness

- 0.5 mm

- Scan rate

- 1 … 10/s

- Brochure

- RAYEX S 110 (PDF, 2.01 MB)

Areas of application

The RAYEX S range supplements our solutions for wall thickness, eccentricity, diameter and ovality testing and is used mainly in the plastic and rubber industries, on tube, cable and hose extrusion systems.

For example: production of pressure hoses, medical hoses, silicone hoses, composite pipes, hoses or multi-layer products, such as medium and high-voltage cables.