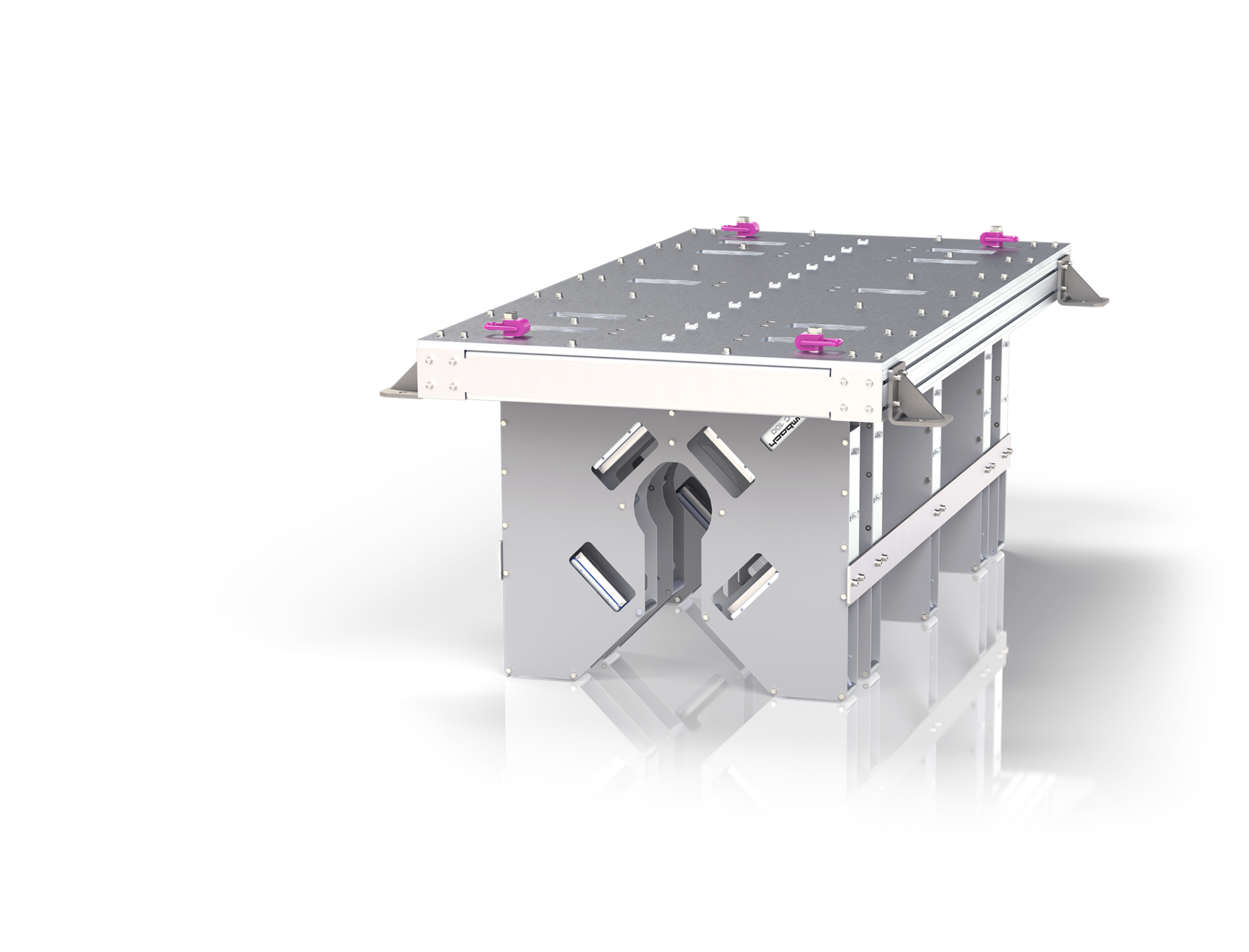

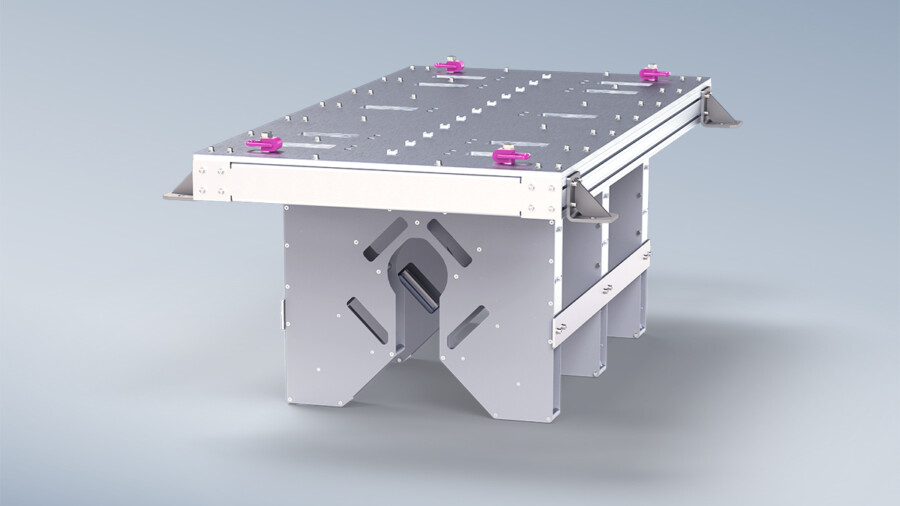

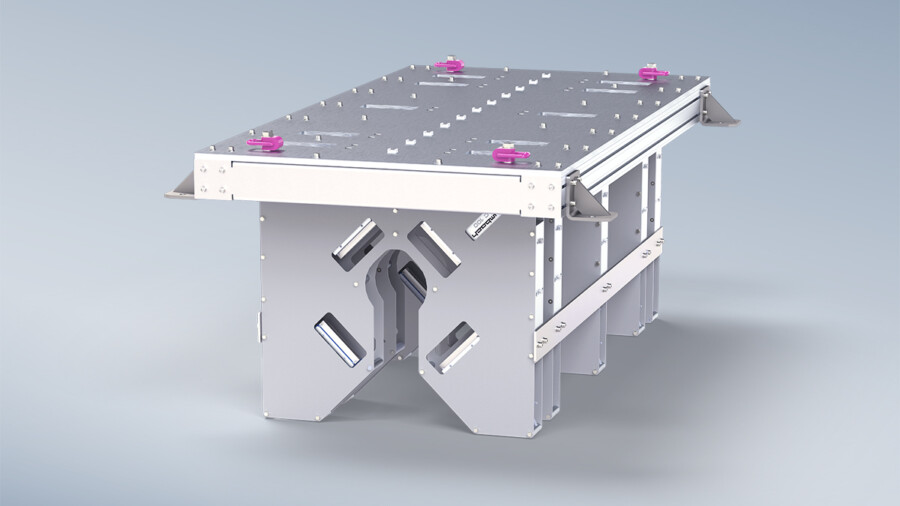

BENDCHECK

In-line laser measuring device for measuring

straightness on rods and tubes

Properties

- Synchronous real-time scan to monitor bending of the product

- 3 to 5 non-contact measuring stations with 1 to 3 measuring axes

- Direct integration into the existing production process

- Constant quality assurance, also after the straightening process

- Recording of statistics, ensuring traceability

- Time savings thanks to automatic measurement control

- Continuous measurement without slowing down the production process

- Replaces manual measurements by means of off-line stations

- Optional measurement of head and tail bending with additional measuring stations

Benefits

- Cutting-edge optics and laser scan technology

- Maximum accuracy and stability

- Extremely high sampling rate

- Comprehensive quality control

- Permanently calibrated

- Extremely dirt resistant

- Robust and durable design

Number of measuring axes

Min. object diameter (mm)

Max. object diameter (mm)

Scan rate (scans/s)

Technical data

For accessories and detailed product information, refer to the respective brochures

BENDCHECK 100

- Measurement points

- 3 / 5

- Recommended max. object diameter

- 90 mm / 3.54″

- Min. object diameter

- 15 mm / 0.6″

- Scan rate

- 1’000/s

- Brochure

- BENDCHECK 100 (PDF, 2.76 MB)

BENDCHECK 160

- Measurement points

- 3 / 5

- Recommended max. object diameter

- 150 mm / 5.9″

- Min. object diameter

- 15 mm / 0.6″

- Scan rate

- 1’000/s

- Brochure

- BENDCHECK 160 (PDF, 2.76 MB)

BENDCHECK 230

- Measurement points

- 3 / 5

- Recommended max. object diameter

- 210 mm / 8.27″

- Min. object diameter

- 15 mm / 0.6″

- Scan rate

- 1’000/s

- Brochure

- BENDCHECK 230 (PDF, 2.76 MB)

BENDCHECK 310

- Measurement points

- 3 / 5

- Recommended max. object diameter

- 290 mm / 11.4″

- Min. object diameter

- 15 mm / 0.6″

- Scan rate

- 1’000/s

- Brochure

- BENDCHECK 310 (PDF, 2.76 MB)

Areas of application

The BENDCHECK system is suitable for in-line production optimization in the steel and metal industry.

The measuring solution enables in-line quality assurance in the production of tubes and rods and eliminates the need for complex manual straightness measurements.