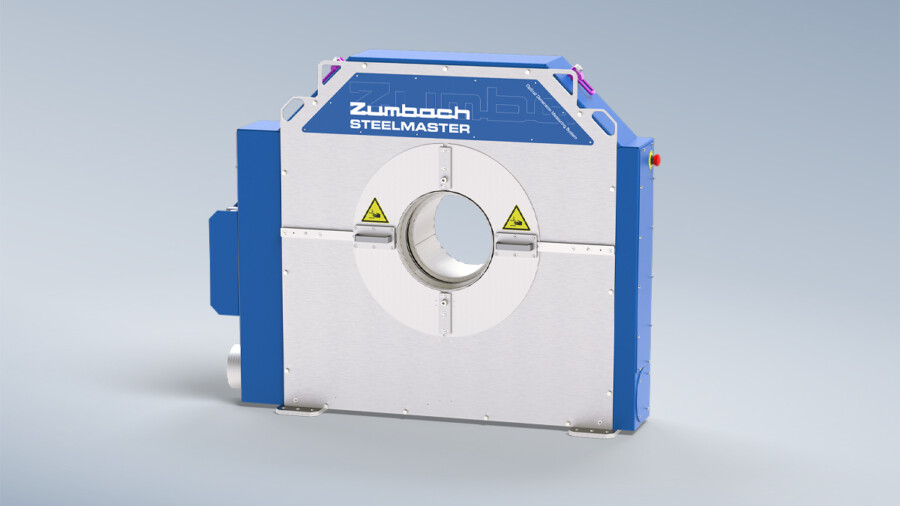

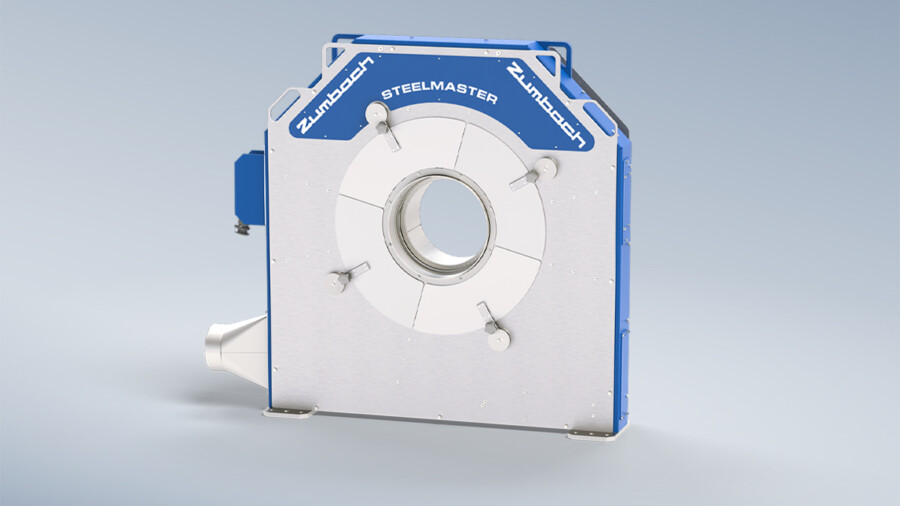

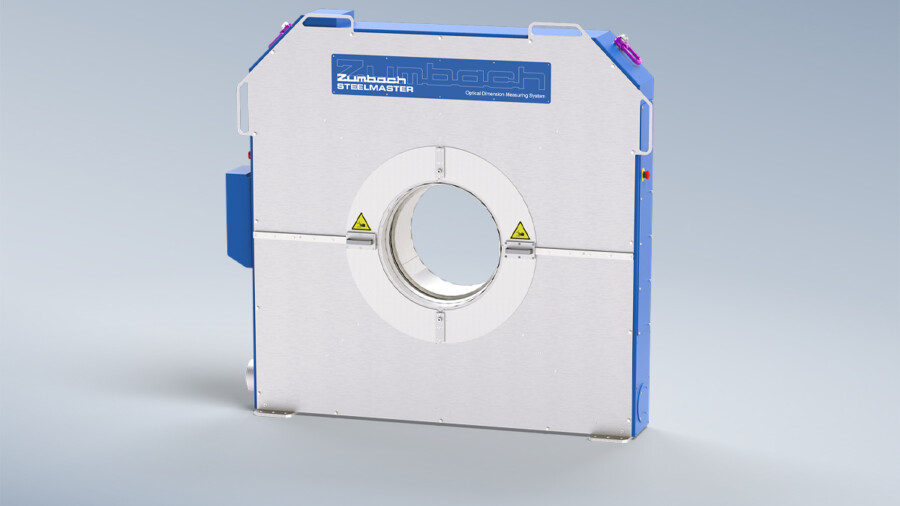

STEELMASTER

Precision laser measuring device for measuring

diameter, ovality, height, width, diagonals and shape variances of hot and cold rolls

Properties

- Application-specific versions: static, oscillating and rotating

- Continuous quality control of the production line

- Up to 6000 measurements per second

- Maximum precision, thanks to new laser technology

- Uncritical guiding

- Measurement of round and non-round products and rods

- Diameter measurement and fault detection over the entire circumference

- Rotation mode option for complete profile measurement

- Non-contact on-line and off-line dimension measurement and monitoring

- Large measuring field

- Product temperature up to 1200 degrees

Benefits

- Tight tolerances (1/2, 1/4 DIN)

- 100% quality control and low fault rate

- Higher productivity thanks to faster start-ups and fewer downtimes

- Simple, robust and mechanical design

- Low service and maintenance costs thanks to the non-contact energy transmission technology SMR and the design concept

- Unique protective system with high reliability

- Non-contact measurement with high precision and reliability

Number of measuring axes

Min. object diameter (mm)

Max. object diameter (mm)

Scan rate (scans/s)

Technical data

For accessories and detailed product information, refer to the respective brochures

SMO 100-Sx

- Measuring axes

- 2 / 3 / 4 / 6

- Recommended max. object diameter

- 80 mm / 3.15″

- Min. object diameter

- 4 mm / 0.16″

- Scan rate

- Standard: 1,000 Hz

Option: 2,000 Hz - Brochure

- SMO 100-Sx (PDF, 3.47 MB)

SMO 160-Sx

- Measuring axes

- 2 / 3 / 4 / 6

- Recommended max. object diameter

- 145 mm / 5.7″

- Min. object diameter

- 4 mm / 0.16″

- Scan rate

- Standard: 1,000 Hz

Option: 2,000 Hz - Brochure

- SMO 160-Sx (PDF, 3.47 MB)

SMO 230-Sx

- Measuring axes

- 2 / 3

- Recommended max. object diameter

- 210 mm / 8.27″

- Min. object diameter

- 4 mm / 0.16″

- Scan rate

- Standard: 1,000 Hz

Option: 2,000 Hz - Brochure

- SMO 230-Sx (PDF, 3.47 MB)

SMO 310-Sx

- Measuring axes

- 2 / 3

- Recommended max. object diameter

- 280 mm / 11″

- Min. object diameter

- 4 mm / 0.16″

- Scan rate

- Standard: 500 Hz

Option: 1,000 Hz - Brochure

- SMO 310-Sx (PDF, 3.47 MB)

SMO 550-Sx

- Measuring axes

- 2

- Recommended max. object diameter

- 520 mm / 21.5″

- Min. object diameter

- 4 mm / 0.16″

- Scan rate

- Standard: 500 Hz

Option: 1,000 Hz - Brochure

- SMO 550-Sx (PDF, 3.47 MB)

SMR 100-Sx

- Measuring axes

- 1 / 2 / 3

- Recommended max. object diameter

- 80 mm / 3.15″

- Min. object diameter

- 4 mm / 0.16″

- Scan rate

- 2,000 Hz

- Brochure

- SMR 100-Sx (PDF, 3.38 MB)

SMR 160-Sx

- Measuring axes

- 1 / 2 / 3

- Recommended max. object diameter

- 145 mm / 5.7″

- Min. object diameter

- 4 mm / 0.16″

- Scan rate

- 2,000 Hz

- Brochure

- SMR 160-Sx (PDF, 3.38 MB)

SMS 100-Sx

- Measuring axes

- 2 / 4 / 6

- Recommended max. object diameter

- 80 mm / 3.15″

- Min. object diameter

- 4 mm / 0.16″

- Scan rate

- Standard: 1,000 Hz

Option: 2,000 Hz - Brochure

- SMS 100-Sx (PDF, 3.15 MB)

Areas of application

The static in-line measuring systems are suitable for production optimization of wire, steel bar and tube rolling mills, as well as warm and cold applications (SMS).

The measuring system is ideal for precise and reliable dimension and shape measurements in the steel and metal industry. It enables reliable quality control for warm and cold rolling processes.

The Steelmaster is the optimal solution for high line speeds and for applications where a 360° detection of short faults around the circumference is necessary.

Today, more than 400 measuring systems are in use in hot rolling processes and thousands in cold processes.