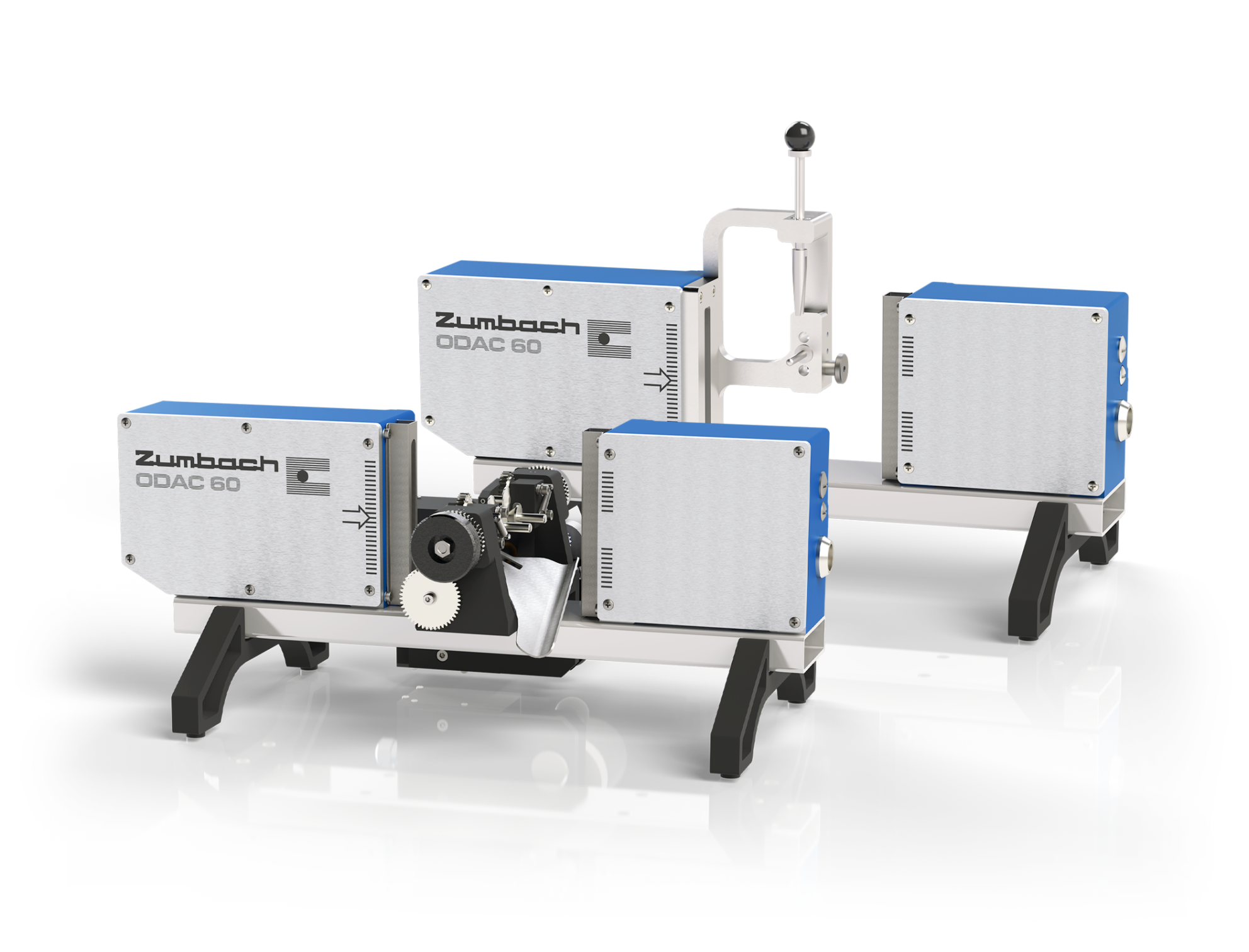

QC

Off-line measuring device for measuring

diameter, ovality and wall thickness of

wire, cable and tube samples

Properties

- Automatic off-line quality control system

- Motorized rotating sample holder with automatic sample ejection

- For use in quality control laboratory (QC) or in production

- Immediate notification of whether specification is met within given tolerances

- Quick feedback for production optimisation

- Minimum, maximum, average and standard deviation calculated for each sample

Benefits

- Fast and accurate measurements of manufactured parts or cut samples

- High precision thanks to laser scan measuring principle

- Own software for evaluating the captured values

Number of measuring axes

Min. object diameter (mm)

Max. object diameter (mm)

Scan rate (scans/s)

Technical data

For accessories and detailed product information, refer to the respective brochures

ODAC® QC 2

- Measuring axes

- 1

- Recommended max. object diameter

- 18 mm

- Min. object diameter

- 0.25 mm

- Scan rate

- 1,000 scans/s

- Brochure

- ODAC® QC 2 (PDF, 895.29 KB)

ODAC® QC 4

- Measuring axes

- 1

- Recommended max. object diameter

- 50 mm

- Min. object diameter

- 1 mm

- Scan rate

- 2,000 scans/s

- Brochure

- ODAC® QC 4 (PDF, 988.18 KB)

Areas of application

The off-line measuring stations can be used to inspect cut samples of extruded products during production. The system is also suitable for performing individual and manual inspection measurements on manufactured production parts.