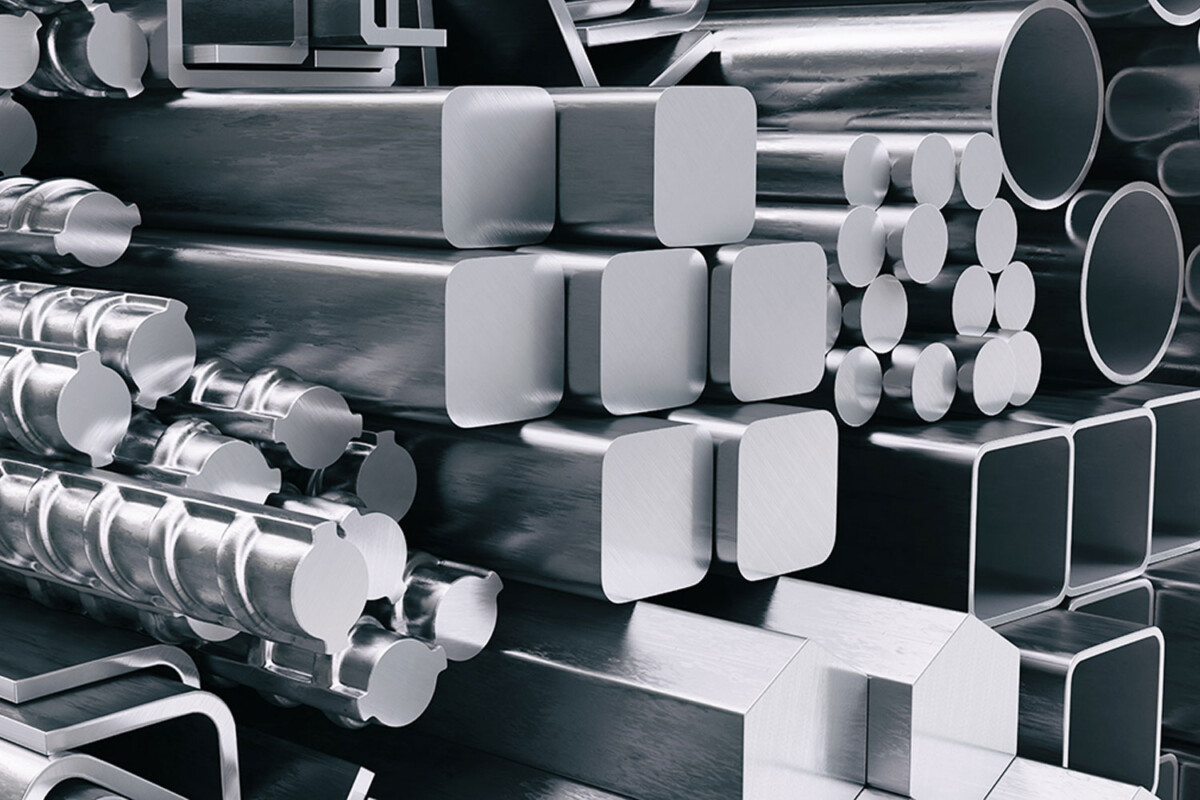

Steel – Cold

Zumbach offers non-contact measuring and fault detection systems for process and quality optimization, for example in your production of tubes, rods and profiles.

Zumbach products measure:

- Outer diameter

- Ovality

- Roundness

- Wall thickness

- Dimensions

The benefits

- On-line production monitoring and inspection

- Continuous analysis and quality monitoring

- Optimization of processes and productivity

- Reduction of production faults and production downtimes

- Cost reduction through material savings

Measuring solution for the following areas of application

Zumbach offers measuring solutions for tube extrusion and tube welding processes. Our measuring solutions can improve your production of tubes, rods and profiles.

With Zumbach measuring systems, measuring values can be displayed, monitored and controlled directly in real time during the production process. This enables you to perform constant quality assurance during production. The optimization is based on a continuous statistical analysis with which the process is optimized to reach its full potential, taking into account any machine instabilities that might exist.

Suitable for production of the following products

- Tubes

- Structural tubes, metal hoses and tubes, tool steel for the aviation and automotive industry

- Rods

- Rebars and rods for the medical industry

- Profiles

- Profiles for the automotive and aviation industry