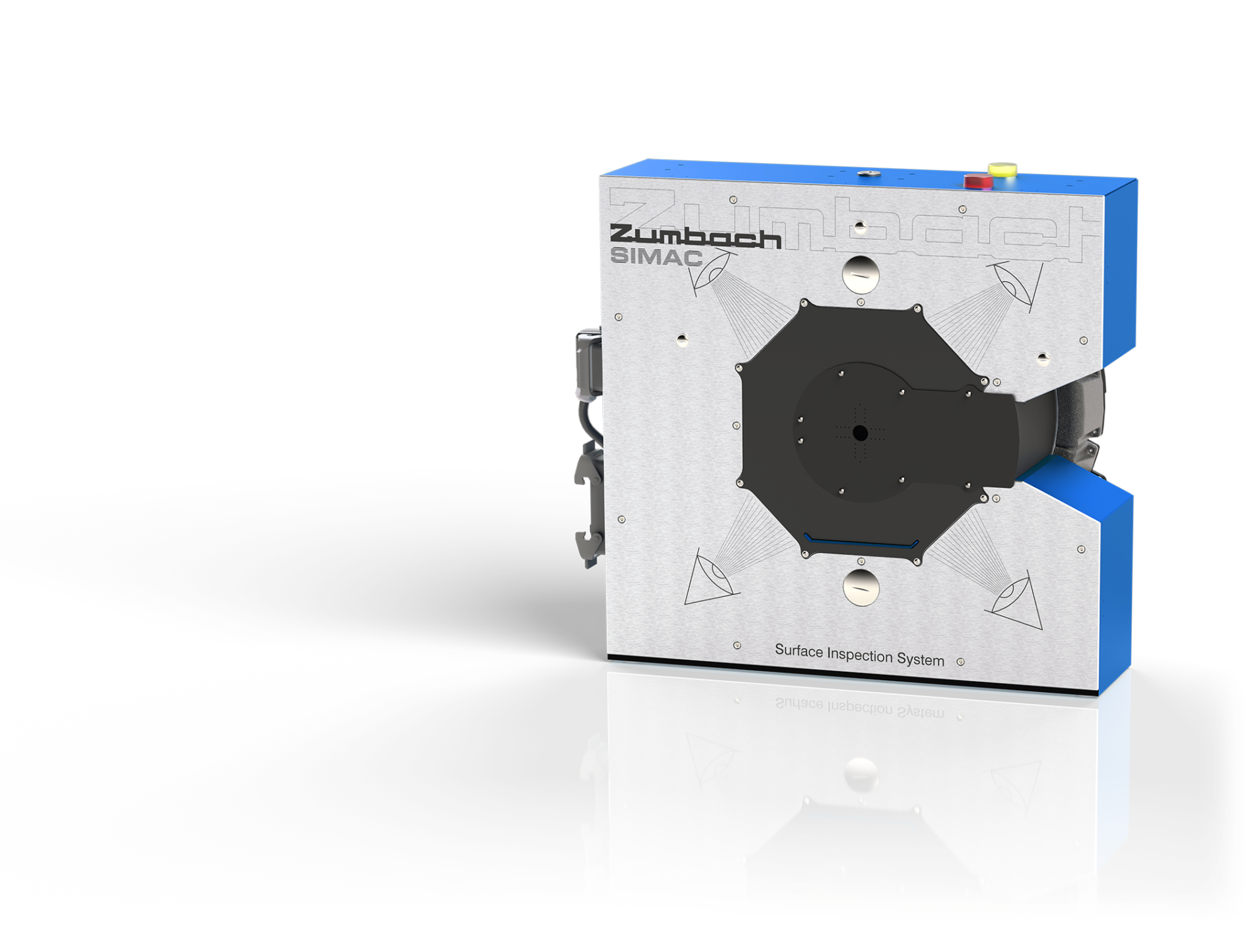

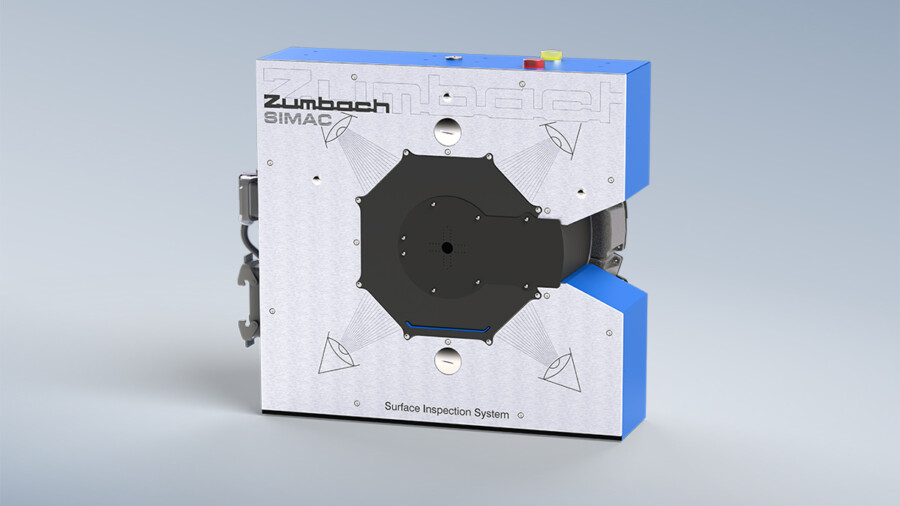

SIMAC®

For testing, inspection and detection of surface faults on cables, tubes and hoses

Properties

- Continuous quality control

- Can be integrated directly into the production line

- Fault detection from as small as 0.1 x 0.1 mm

- Up to a line speed of 500 m/min

- Easy operation, thanks to touchscreen

Benefits

- Easy operation thanks to modern graphical user interface

- Highly compact design

- Clear and crisp image

- LED light system with CCD camera

- Length-related scanning and fault detection

Line speed (m/min)

Min. object diameter (mm)

Max. object diameter (mm)

Scan rate (scans/s)

Technical data

For accessories and detailed product information, refer to the respective brochures

SIMAC 40

- Recommended max. object diameter

- 36 mm / 1.4″

- Min. fault resolution

- Typically 0.1 x 0.1 mm at 125 m/min

- Scan rate

- Up to 35,000 scans/s

- Line speed

- Theoretically unlimited, depending on the fault resolution

- Brochure

- SIMAC 40 (PDF, 3.5 MB)

SIMAC 70

- Recommended max. object diameter

- 63 mm / 2.48″

- Min. fault resolution

- Typically 0.1 x 0.1 mm at 125 m/min

- Scan rate

- Up to 35,000 scans/s

- Line speed

- Theoretically unlimited, depending on the fault resolution

- Brochure

- SIMAC 70 (PDF, 3.5 MB)

SIMAC 120

- Recommended max. object diameter

- 108 mm / 4.25″

- Min. fault resolution

- Typically 0.1 x 0.1 mm at 125 m/min

- Scan rate

- Up to 35,000 scans/s

- Line speed

- Theoretically unlimited, depending on the fault resolution

- Brochure

- SIMAC 120 (PDF, 3.5 MB)

Areas of application

Suitable measuring solution for the production of extruded products such as tubes, cables and hoses. With the SIMAC system, even the tiniest surface faults on the periphery of the product can be detected accurately.

Additionally, the SIMAC is frequently successfully used for process optimization in the following applications:

- Cables

- Water and composite pipes

- Gas and car pipes

- Rubber hoses